Contact

Contact

Administrative CH +41 52 212 02 77 / DE +49 2064 144 3005

T +41 52 212 02 77Technical support +41 52 511 83 11

T +41 52 511 83 11Please call me back

Please call me back

coatmaster AG

Headquarters

Flugplatzstrasse 5

CH-8404 Winterthur

+41 52 212 02 77 (Administration)

+41 52 511 83 11 (Technical Support)

Send an email to:

[email protected] (Administration)

[email protected] (Technical Support)

References

That's what our customers say about the coatmaster...

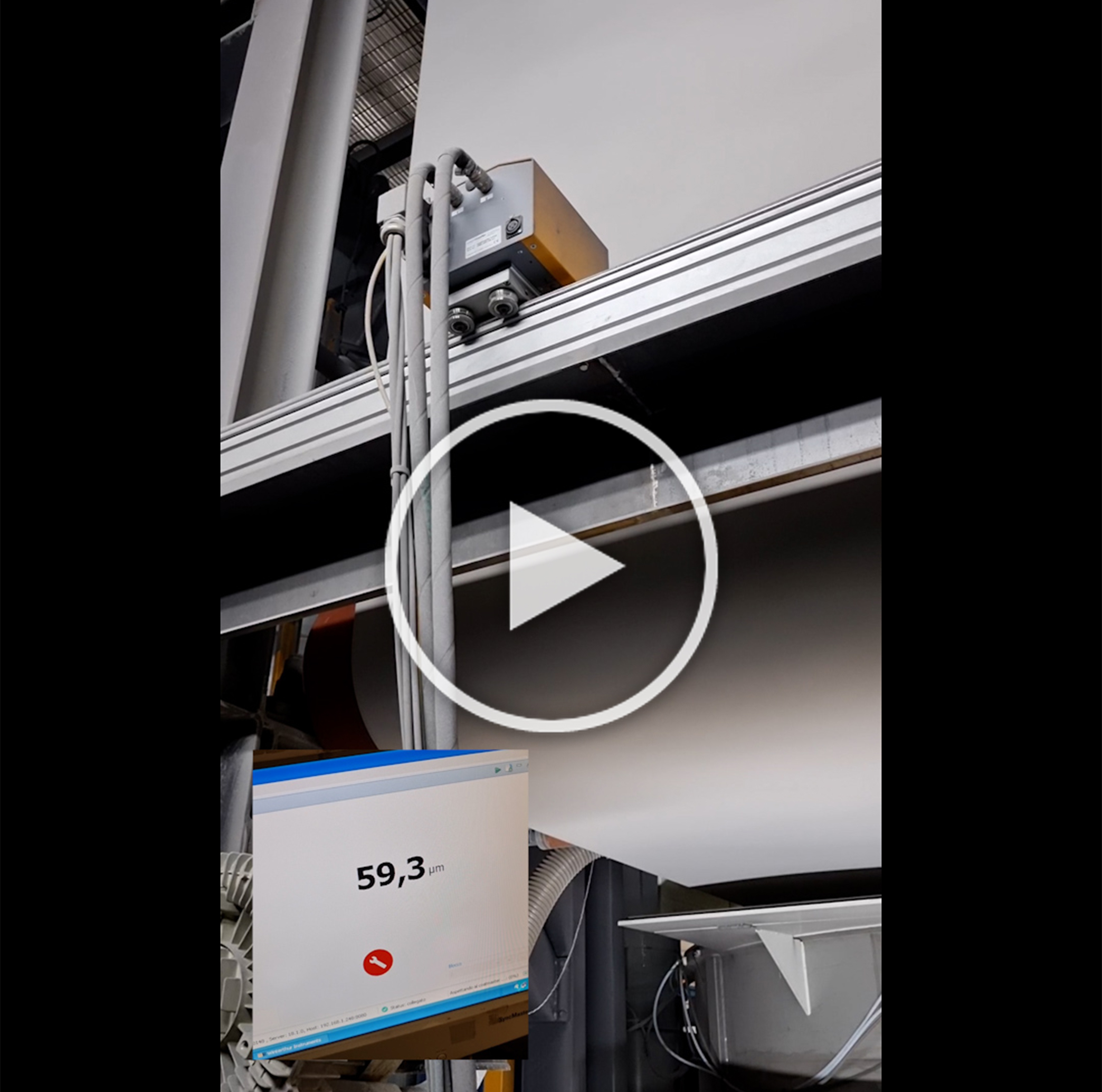

The coatmaster is used at more than 2000 locations for the early monitoring of layer thickness. The coatmaster is also the heart of a steadily growing number of autonomous and highly efficient coating systems. The precision achieved with the coatmaster increases the quality of produced goods, saves coating material and avoids rejects. At the same time, layer thicknesses are continuously recorded.

Coating quality with coatmaster