The coatmaster enables comprehensive process monitoring. It determines coating thicknesses without contact and offers closed-loop control of the coating process and thus provides the missing component for a fully automated coating system. This integrated coating thickness measurement process allows massive material savings and quality improvements. The patented and unique technology is already a central component of many production processes in leading industrial companies.

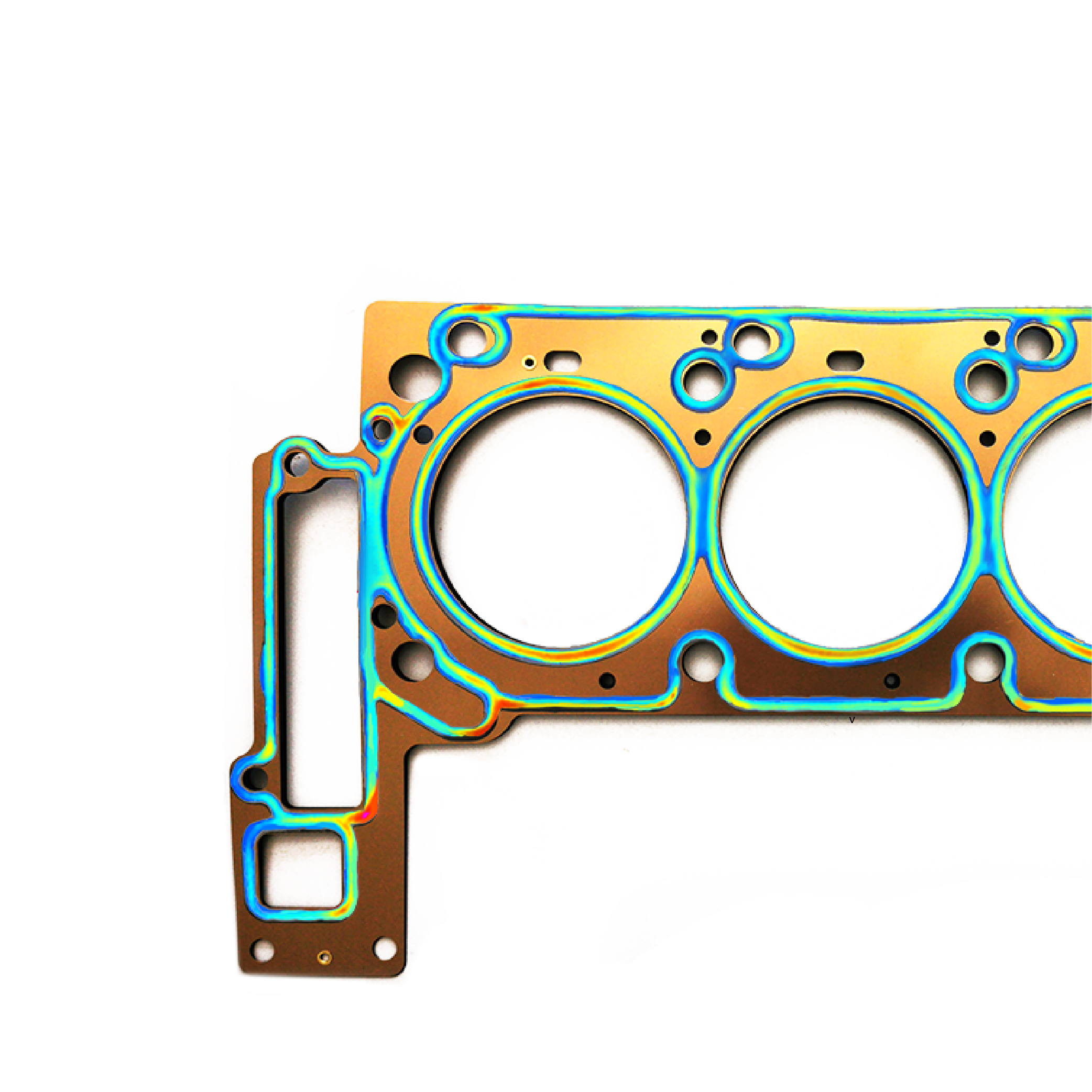

coatmaster is compatible with all types of coatings and substrates, resulting in a wide range of application possibilities. The suppliers of the automotive industry (wheels, airbags, pistons etc.) are currently the largest user group of the coatmaster. Our measuring systems can be used to determine coating thicknesses, material parameters (e. g. porosity) and contact quality (e. g. to detect delamination). The system is based on optical-thermal measurements.